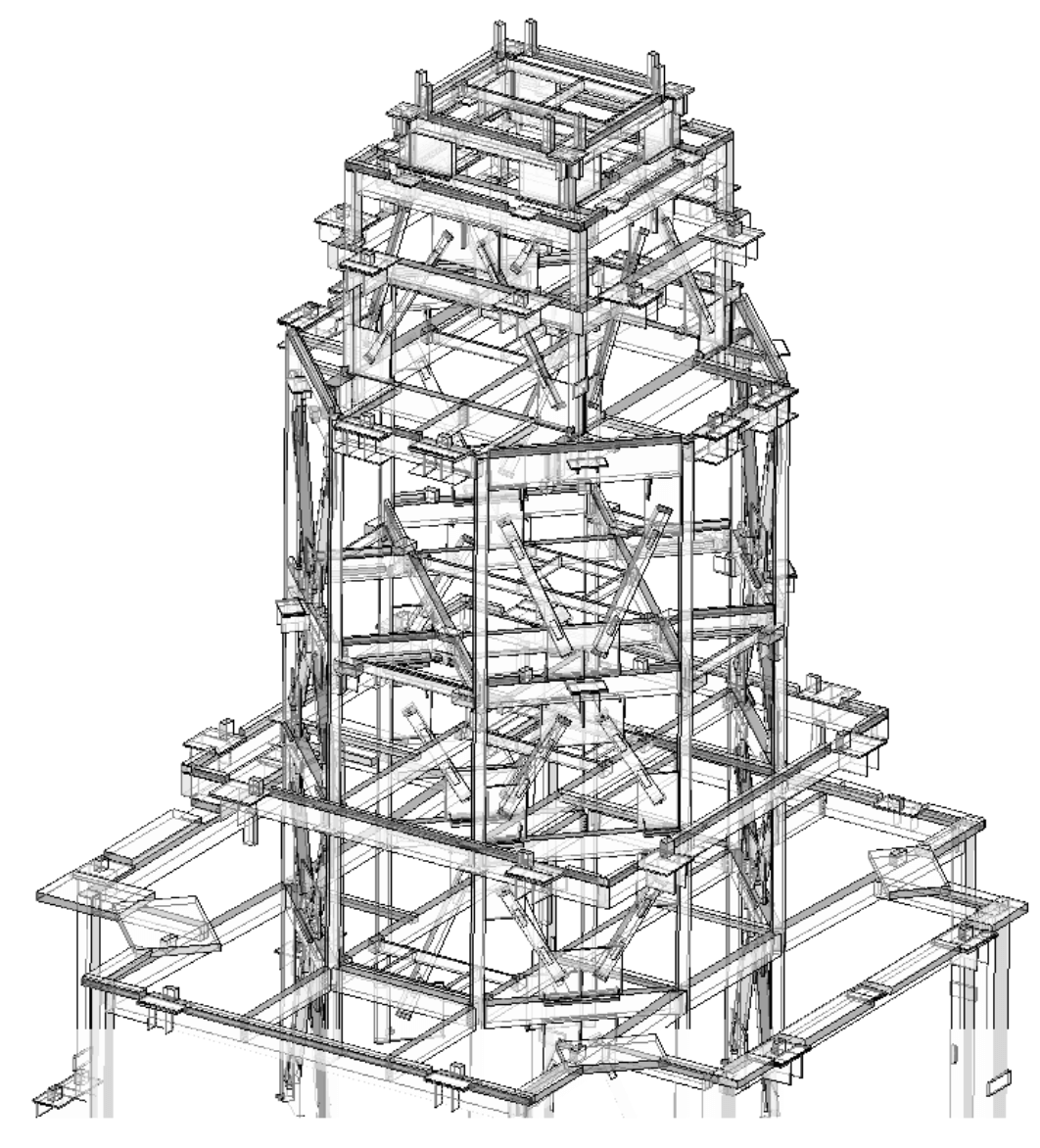

Sure Steel, Inc. uses state of the art 3D Building Information Modeling (BIM) which provides specific building geometry for both the design and construction teams.

This modeling provides accurate information for the project team to aid in identifying any clashes or problem areas before they ever physically occur in the field. Each steel object is embedded with valuable data (weight, piece mark, elevations, etc.) that allows Sure Steel, Inc. to manage each piece with maximum efficiency for schedules, critical paths, and informational output.

Additionally, at completion of the shop drawings, the detailing software will be used to generate a Computer Numeric Control (CNC) file that is directly downloaded to fabrication equipment. Implementation of this software with the automated shop equipment virtually eliminates all errors in the detailing and fabrication process.

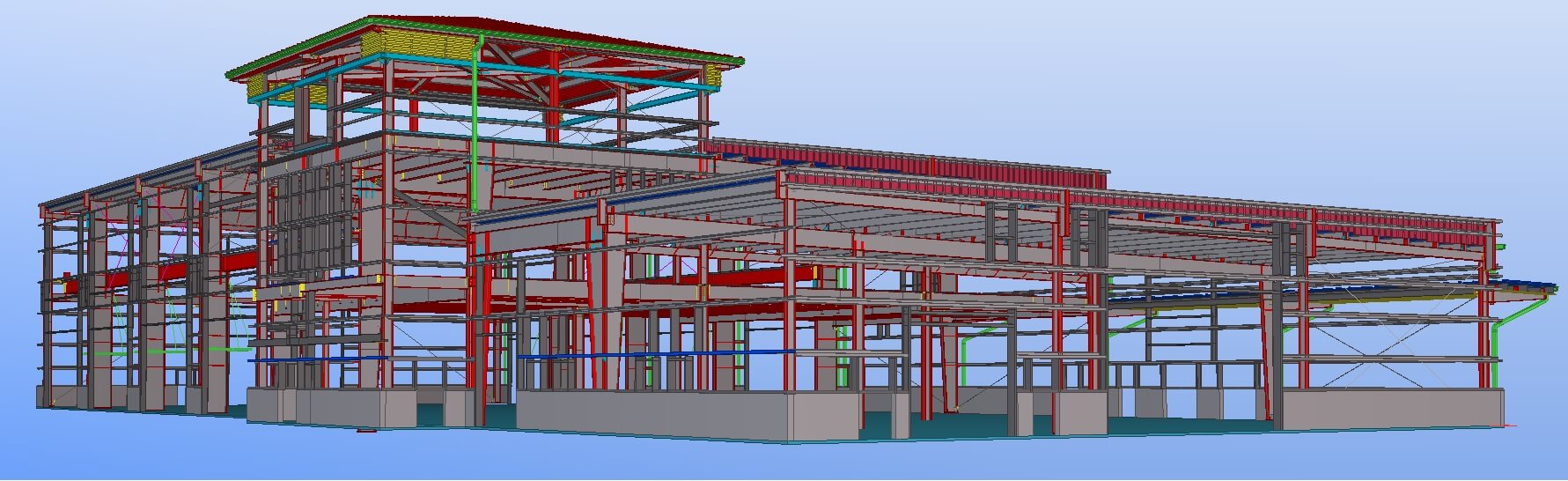

Project Highlight

Fort Bliss Tactical Equipment Maintenance Facilities

- 60 Pre-Engineered Metal Buildings

- 2,381 tons of structural and miscellaneous steel

- 400,000 square feet

- 12 bridge cranes

- 228 overhead doors

- 400,000 square feet of standing seam metal roof

- 366,460 square feet of insulated metal panel cladding

- 72,500 manhours worked